Sekoti se le seng sa strend se futhumatsang se futhumatsang

Litlhaloso

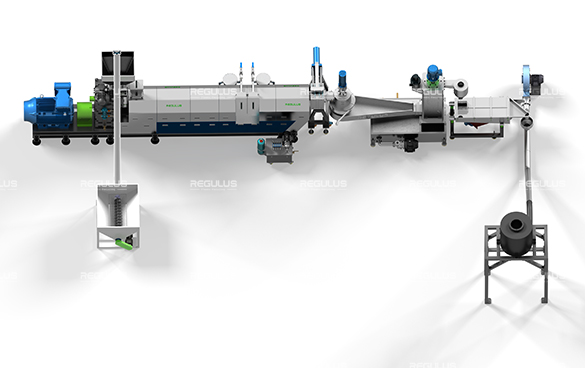

| TLHOKOMELISO E FUMANANG | HDP, LDP, ldpe, PP, bop, opp, opp, ka pc, PC, PC, PC, PC, | |||||

| Sebopeho sa Sisteme | Screw mojari | |||||

| Thepa ea sekoti | 38305), Bimtal (ea boikhethelo) | |||||

| L / D ea screw | 28/1, 30/1, Khutla ka3/1, (ho latela litšobotsi tsa ho nchafatsa) | |||||

| Heater of Barrel | Heater ea ceramic kapa heater ea seriti | |||||

| Ho futhumala ha barrel | Ho futhumala ha moea ho tsoa ho ba bang | |||||

| Mofuta oa pelletizing | Metsi-peeletso ea metsi e peletizing / metsi a phatsimang / tlasa metsi a phatsimang | |||||

| Litšebeletso tsa mahlale | Moralo oa Morero, kaho ea fektheri, ho kenngoa litlhahiso, ho kopanya | |||||

| Mochine oa mochini | L / d | Sekoti se le seng sextruder | ||||

| Screw bophara | Motor eastrrdier | Bokhoni ba tlhahiso | ||||

| (mm) | (kw) | (kg / h) | ||||

| Xy100 | 100 | 33 | 75-90 | 200-300 | ||

| Xy120 | 120 | 33 | 90-110 | 250-400 | ||

| Xy130 | 130 | 33 | 132 | 450-550 | ||

| Xy160 | 160 | 33 | 160-200 | 550-850 | ||

| Xy180 | 180 | 33 | 220-250 | 800-1000 | ||

Pelletizing moneo

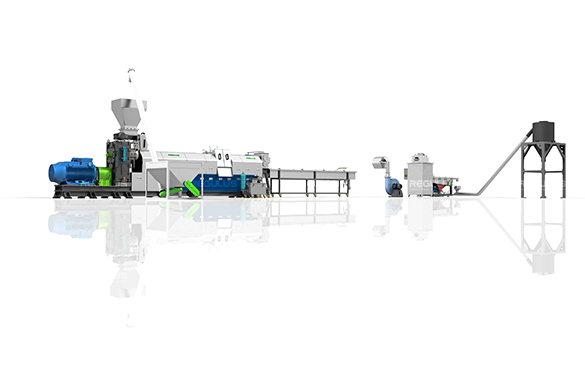

Litokisetso tsa seretse se sa tsoakoang le tsa pelletisa ke sistimi e ikhethileng le e tšepahalang, e loketseng ho nchafatsa polasetiki ea polasetiki ea polasetiki hape. E kopanya ts'ebetso ea polasetiki le ho petetsa mohato o le mong mme o loketse hore o itekanetse kapa o be le lipalesa tsa pe / pp / letheba / ps / hs /.

Lihlahisoa tsa ho qetela tse hlahisoang ke mohala o le mong oa li-pellets / granules, li ka kenya ka kotloloho moleng oa tlhahiso, o ile a fetoha ka ente ea polasetiki, joalo-joalo

Mochini oa ho fepa ka spiral

Li-flakes kapa li-flakes tse teteaneng ka mor'a ho sithabela, li fetisetsoa ka seqhetsoana se le seng ka ho senyeha, ka mor'a ho chesoa ka sistimi, ho penta granules. Ho ipapisitse le li-screw tse fapaneng tsa sekoti se le seng Ho fetisa phala ho entsoeng ka thepa ea tšepe e se nang mabele, lipeipi tse ntle ke 2mm, bophara ba lipee ke 102mm.

Setsi se ka sehloohong (bophahamo ba bophahamo)

E tla fepa thepa e le monyetsang. Ho na le screw e hlohlelletsang ho qoba li-block tsa thepa ka tlase ho ea fepa. Ho fepa hopper ka sesupo sa boemo.

Haeba u batla ho sebelisa lisebelisoa, li-feed tsa lehlakore ke tsa boikhethelo.

Sekoti se le seng sextruder

Moralo oa rona o ikhethang o ile oa senyeha ka bonolo polasing ea lifofane le ho bonesa lisebelisoa. Setsoalle sa rona se nang le tšepe se na le anti-Corsusant e matla e loantšanang, e roala nako e telele ea bophelo le nako e telele.

Libaka tsa li-vacuum tsa liteko tse habeli

Ka libaka tse sa lefelloeng habeli tse sa sebetseng hantle joalo ka limolek'hule tsa micro-limolek'hule tse ngata le mongobo li tla tlosoa ho ntlafatsa lisebelisoa tsa granules, haholoholo bakeng sa lisebelisoa tse boima tse hatisitsoeng.

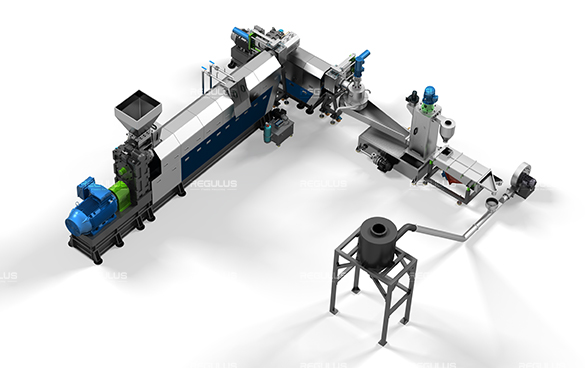

Change Mofuta oa Sekene sa Plate

Mofuta oa mofuta oa poleiti o etsoa ka mofuta o tsoelang pele ka lipolanete tse peli tsa tsamaiso. Bonyane ho sebetsa ha skrini se le seng ha skrini se ntse se fetola heater ea.Pe-e halikiloeng

Leha ho le joalo, emisa filthara ea mofuta oa piston

1.A e tloaelehileng ea skrini e tloaelehileng / piston e sa fetoheng

Mmila oa Screen ea 2. Kama

3. Ho bonolo ho sebelisa mofuta o se nang moeli: phetoho ea skrineng e bonolo le e potlakileng ebile ha e hloke ho emisa mochini o boima.

4. Veril e tlase e sebetsa.

Trup Mold

Mold Mold e sebelisoa haholo, 'me thepa e tala e joalo ka PP, pe, ea joalo, pe, pet, jj. E ka sebelisoa moruong le moruo

Mabone a polasetiki a mabopo a futhumatsang tanka

1.DVANTD e siuoa e siameng e kopanyang le centrifugal e tsoang pele e qaqileng ea li-pellets tse omisitsoeng le tatellano e tlase.

2. Bokella methapo: Maheso a kentsoe 'me a behiloe ke likhakanyo tsa ho palama, ka hona o ka fetola tsamaiso ea hae nakong e tlang.

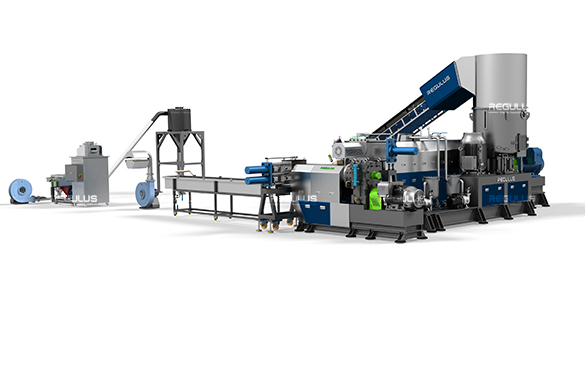

Granulation granulation Line e futhumetse

E sebedisoang bakeng sa ho tlosa mongobo ho tloha polasetikibraces

Mohala oa polasetiki oa mela

E sebelisoang bakeng sa ho cheka metsero ea polasetiki ho ba likaroloana

Skrineng

Sebelisoa ho arola boholo ba likaroloana tsa polasetiki