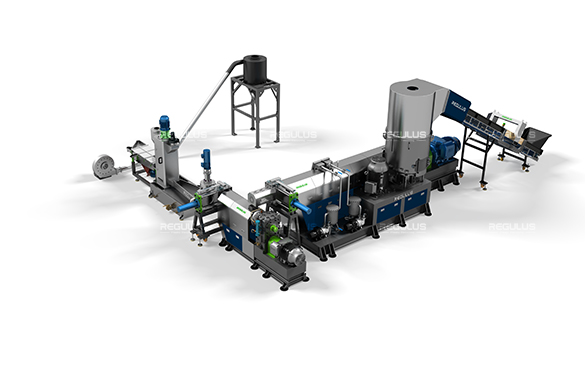

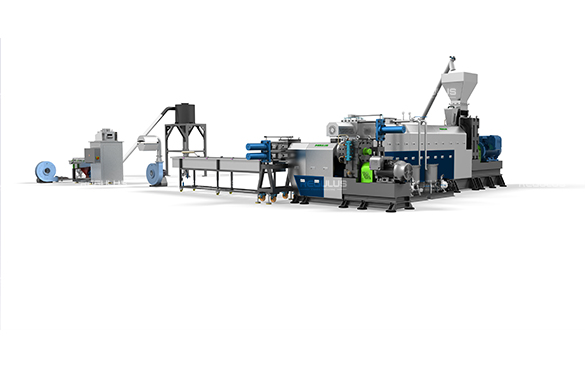

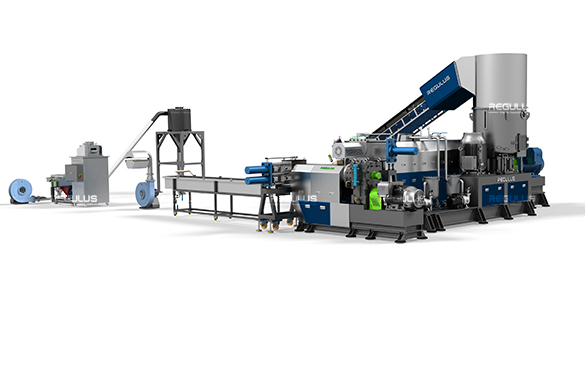

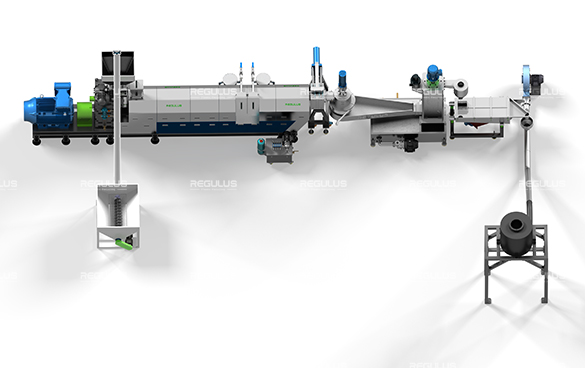

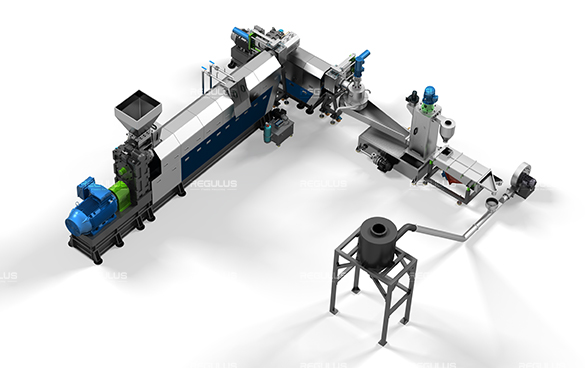

Karolo ea Karolo ea Double Compaction le mola oa tlhahiso ea granulation bakeng sa filimi ea pet ea pep

Litlhaloso

| TLHOKOMELISO E FUMANANG | HDP, LDP, ldpe, PP, bop, opp, opp, ka pc, PC, PC, PC, PC, | |||||

| Sebopeho sa Sisteme | Belt Convyoror, morekisi oa ho khaola, moqapi o le mong ea iphetetsang,Pelletizer, Karolo e futhumetseng ea metsi, karolo e nang le metsi a mangata, tsamaisa fan ea fan, Silo ea sehlahisoa. | |||||

| Thepa ea sekoti | 38305), Bimtal (ea boikhethelo) | |||||

| L / D ea screw | 28/1, 30/1, Khutla ka3/1, (ho latela litšobotsi tsa ho nchafatsa) | |||||

| Heater of Barrel | Heater ea ceramic kapa heater ea seriti | |||||

| Ho futhumala ha barrel | Ho futhumala ha moea ho tsoa ho ba bang | |||||

| Mofuta oa pelletizing | Metsi-peeletso ea metsi e peletizing / metsi a phatsimang / tlasa metsi a phatsimang | |||||

| Litšebeletso tsa mahlale | Moralo oa Morero, kaho ea fektheri, ho kenngoa litlhahiso, ho kopanya | |||||

| Mochine oa mochini | Morekisi | L / d | Sekoti se le seng sextruder | |||

| Buka | MOSEBETSI OA MOTLE | Screw bophara | Motor eastrrdier | Bokhoni ba tlhahiso | ||

| (Litha) | (kw) | (mm) | (kw) | (kg / h) | ||

| Xy-85 | 350 | 37 | 85 | 28 | 55 | 150-250 |

| 10 | 22 | |||||

| Xy-100 | 500 | 55 | 100 | 28 | 90 | 250-350 |

| 10 | 30 | |||||

| Xy-130 | 850 | 90 | 130 | 28 | 132 | 450-550 |

| 10 | 45 | |||||

| Xy-160 | 1100 | 110-132 | 160 | 28 | 185 | 650-800 |

| 10 | 55 | |||||

| Xy-180 | 1500 | 185 | 180 | 28 | 250-280 | 900-1100 |

| 10 | 90 | |||||

Compactor Compactor polasetiki ea polasetiki ea pellesingo

Limitisi tsa khato le tsa pelleti lia kopanya ts'ebetso ea ho hatella, ho bapisoa, polasetiki le ho petsola mohato o le mong. E sebelisoa ka har'a polasetiki ea ho nchafatsa le ts'ebetso ea pelletizing. Sistimi ea ACH TM ke tharollo e tšepahalang le e sebetsang bakeng sa filimi ea baptics, Raffidente, mekotla, mekotla e lohiloeng ea mochini oa ts'ebetso .lower E ka fana ka tlhahiso e holimo empa e na le khatello ea matla a tlase. Kopo: Pe, PP, Ps, ABS, XPS, eps, pvb.

Ho fepa

Joaloka moralo o tloaelehileng, lipompo tsa polasetiki tse kang filimi, se fihla, Raffias o ile a fetisetsa kamoreng e kopane ka kamoreng ea libethe ka har'a mlt doverver; Ho sebetsana le li-roll 'scaraps, roll autting of sesebelisoa ke mokhoa oa ho iphepa. Li-drive tsa motor tsa conveyor le ho hula li sebelisana le li-Intarter. Lebelo la ho fepa lebanta la conveyr kapa roll ha le felisitsoe ka mokhoa o ikemetseng ho ipapisitse le hore kamore ea khoebo e felletse hakae.

Ho sithabetsa le ho kopanya

Morekisi o na le sesebelisoa se khathollang sa moea. Ka mosebetsi oa mochini oa thipa ea thipa le thekeithara le ho eketseha butle-butle, le mongobo o holim 'a ho reha ka mokhoa o sa feleng. Sesebelisoa se ka tlosa mongobo le lerōle, tse tla qoba ho sebelisa ts'ebeliso e 'ngoe ea matla a ho sebetsana le mongobo. Mokhoa o folisang o omileng le o tsitsitsengts'ebetso ea ho fepa.

Li-Blace tsa Rotatory tsa Compactor

Lebato le potolohang le lehare le tsitsitseng le khaola boitsebiso bo bobebe. Ho futhumatsa likhohlano tse hlahisitsoeng ke li-blamati tse phahameng ka lebelo ho tla chesa le mocheso le ho li senya mala.

Sekoti se le seng sextruder

Moralo oa rona o ikhethang o ile oa senyeha ka bonolo polasing ea lifofane le ho bonesa lisebelisoa. Setsoalle sa rona se nang le tšepe se na le anti-Corsusant e matla e loantšanang, e roala nako e telele ea bophelo le nako e telele.

Libaka tsa li-vacuum tsa liteko tse habeli

Ka libaka tse sa lefelloeng habeli tse sa sebetseng hantle joalo ka limolek'hule tsa micro-limolek'hule tse ngata le mongobo li tla tlosoa ho ntlafatsa lisebelisoa tsa granules, haholoholo bakeng sa lisebelisoa tse boima tse hatisitsoeng.

Change Mofuta oa Sekene sa Plate

Mofuta oa mofuta oa poleiti o etsoa ka mofuta o tsoelang pele ka lipolanete tse peli tsa tsamaiso. Bonyane ho sebetsa ha skrini se le seng ha skrini se ntse se fetola heater ea.Pe-e halikiloeng

Leha ho le joalo, emisa filthara ea mofuta oa piston

1.A e tloaelehileng ea skrini e tloaelehileng / piston e sa fetoheng

Mmila oa Screen ea 2. Kama

3. Ho bonolo ho sebelisa mofuta o se nang moeli: phetoho ea skrineng e bonolo le e potlakileng ebile ha e hloke ho emisa mochini o boima.

4. Veril e tlase e sebetsa.

Sisteme ea metsi a phoroselang ea methapo ea kutlo

1. Ho fetola hlooho ea pelletiziin ea pelletizi

2. Rpm ea li-blades tse rotato li itekanetsa ho ipapisa le khatello ea maikutlo.

3.easy le ka potlako Pelletizer Bladesforver, ntle le mosebetsi oa liphetoho o boloka nako.

Sistimi ea metsi e otlolohileng ea metsi

1. Ho fetola hlooho ea pelletiziin ea pelletizi

2. Rpm ea li-blades tse rotato li itekanetsa ho ipapisa le khatello ea maikutlo.

3.easy le ka potlako Pelletizer Bladesforver, ntle le mosebetsi oa liphetoho o boloka nako.

Vibration o omile

1.DVANTD e siuoa e siameng e kopanyang le centrifugal e tsoang pele e qaqileng ea li-pellets tse omisitsoeng le tatellano e tlase.

2. Bokella methapo: Maheso a kentsoe 'me a behiloe ke likhakanyo tsa ho palama, ka hona o ka fetola tsamaiso ea hae nakong e tlang.

Vertical Pickement Dehhyder

E sebelisoang ka ho khetheha bakeng sa ho otloa ka mehele ea metsi a polasetiki le metsi a ka tlasa metsi a ka tlase,

Skrineng

Sebelisoa ho arola boholo ba likaroloana tsa polasetiki